Solution For Your Manufacturing

We provide comprehensive automation solutions designed to optimize your manufacturing processes. Our innovative technologies enhance efficiency, reduce operational costs, and improve product quality while maintaining the highest standards of reliability and performance.

1. Marking Solution

Laser, dot peen, and scribe marking systems for permanent product identification and traceability across industrial applications.

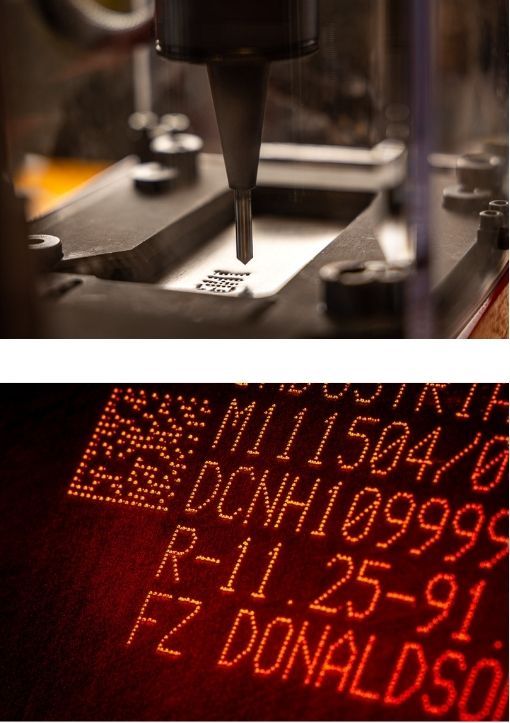

Dot Pen

Dot peen marking or engraving makes it possible to generate permanent, tamper-proof and perennial markings on all types of parts and materials.

Dot peen marking or indented marking is widely used in the automotive industry, pioneering in its overall approach to quality via single component identification systems.

Today, it is present in most industrial sectors.

Our dot peen marking systems are designed to be installed in workshops, for fixed or mobile operation, or for integration into production lines.

SIC Marking Dot Peen Benefits

- All part shapes (flat or cylindrical) or surface finishes

- Deep Marking product options

- High marking accuracy and speed

- No material residue

SIC Marking Dot Peen Solutions

- Dot-peen products for workstation/standalone

- Dot-peen products for production line integration

- Dot-peen products for portable/mobile work

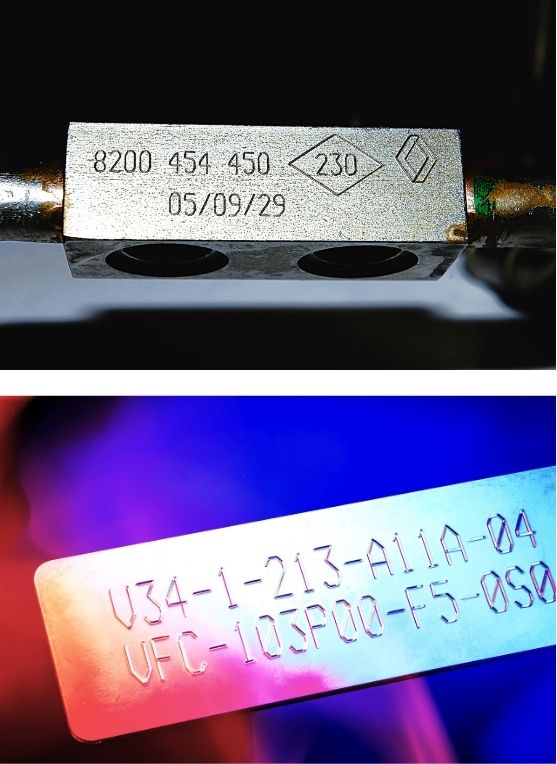

Scribing

Scribe marking delivers fast, high-contrast engravings with exceptional precision on hard steels—enabling deep/hollow markings with minimal noise. Our industrial-grade machines withstand heavy loads while producing permanently legible traces, ideal for demanding sectors like automotive (VIN/chassis), metallurgy, energy, and construction.

Seamlessly integrated into workstations, production lines, or robotic systems, this technology combines rugged durability with aesthetic results for critical part identification.

SIC Marking Dot Peen Benefits

- Best for deep marking options

- High marking accuracy and speed

- Quiet

- Compatible with hardest steels

SIC Marking Dot Peen Solutions

- Dot-peen products for workstation/standalone

- Dot-peen products for production line integration

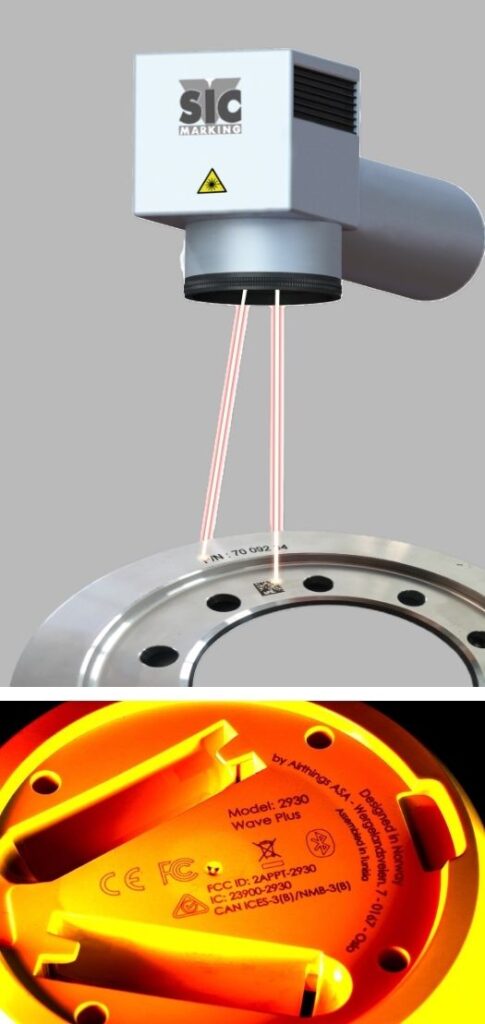

Laser Marking

Laser marking delivers automated, permanent traceability critical for high-quality industrial standards. Ideal for direct engraving on metals and plastics—regardless of hardness or surface conditions—our technology ensures flawless part identification with precision alphanumeric text, logos, and 1D/2D codes (DataMatrix, QR).

Engineered for high-volume production, these systems combine exceptional speed with pixel-perfect accuracy. Easily upgradeable for 3D marking or integrated reading systems, SIC laser machines adapt to your unique specifications while maintaining process control

SIC Marking Laser Technology Benefits

- Precision and fineness of markings

- Versatility of applications and materials (Almost all material)

- Integration flexibility

- Very high definition marking (fibre technology)

- High rates: medium to large series

- Very high rate marking

- No consumables with good endurance machine

SIC Marking Laser Technology Benefits

- Dot-peen products for workstation/standalone

- Dot-peen products for production line integration

2. Automation Handling

Automation handling solutions are designed to streamline material movement and component manipulation across manufacturing processes. Our comprehensive range of handling equipment ensures precise, efficient, and reliable operation in automated production environments, reducing manual intervention while increasing throughput and consistency.

Vacuum Cup

Vacuum cups are pneumatic gripping devices that use negative pressure to securely hold and manipulate objects. These suction-based components create a temporary seal against surfaces to enable safe lifting and transfer. They are ideal for:

- Smooth-surfaced materials such as glass, plastic, sheet metal, and finished products

- Applications requiring gentle handling without marking or damaging delicate surfaces

- Automated pick-and-place operations in packaging, assembly, and logistics systems Vacuum cups come in various shapes, sizes, and materials to accommodate different surface geometries and environmental conditions.

Gripper

Grippers are mechanical devices designed to physically grasp and secure objects during automated handling processes. Using controlled force application, they provide precise object manipulation. They are perfect for:

- Complex part geometries requiring secure multi-point contact

- Applications demanding high positional accuracy in assembly and manufacturing

- Handling systems in electronics, automotive, and general manufacturing industries Available in parallel, angular, and specialized configurations to suit various industrial requirements.

Vacuum Pump

Vacuum pumps are the power source for suction-based handling systems, creating the negative pressure necessary for vacuum cups to function. These engineered pumping systems are essential for:

- Continuous material handling operations requiring consistent vacuum levels

- Applications with varying cycle times and production speeds

- Integrated automation systems where reliable pneumatic power is critical Available in centralized or decentralized configurations to optimize energy efficiency and system performance.